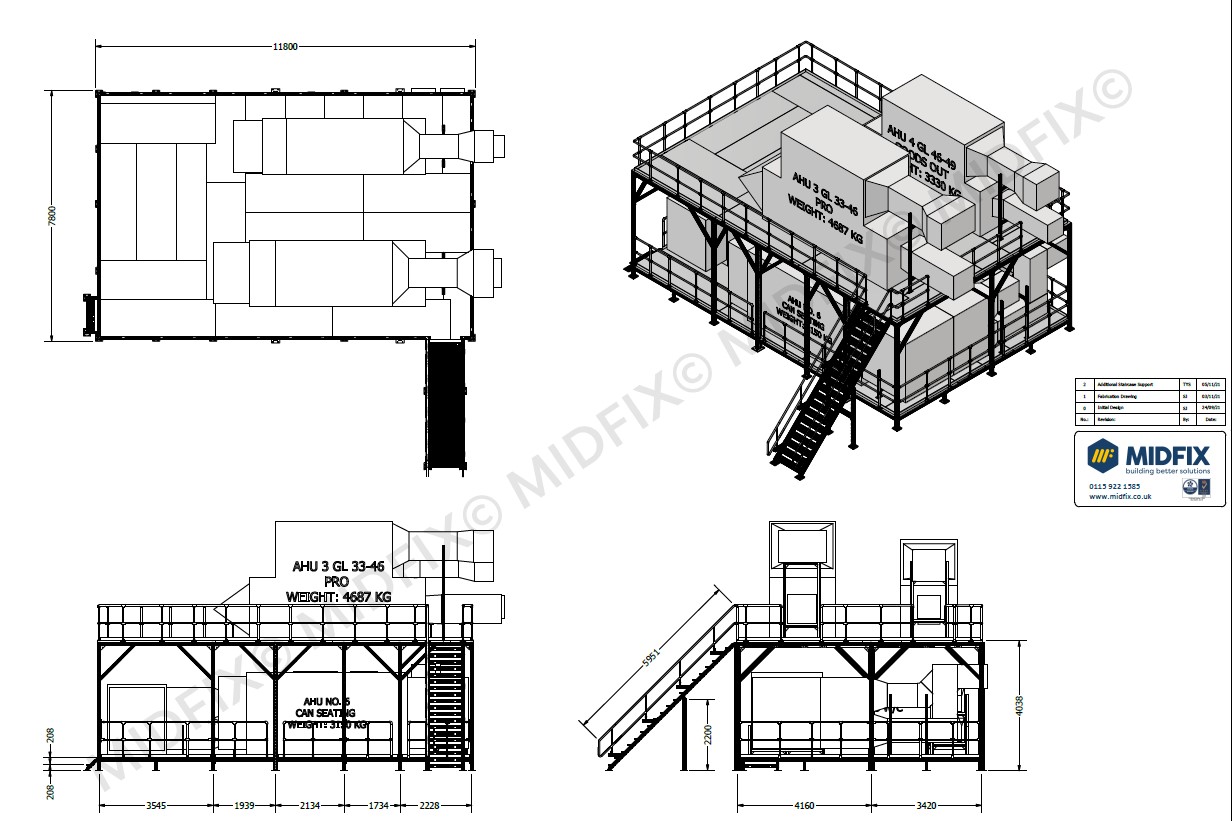

Project brief: Design a large access platform for maintenance purposes of 4 AHU units and associated ducting. Our Senior Design Engineer, Skye Jennings provided some insights into the process of designing this access platform for our customer.

Access Platform (Source: Imtech Engineering Services)

There were several considerations to keep in mind.

Preliminary Discussion

First, it was agreed from the outset that we would carry out wind load calculations to ensure that the design was fit-for-purpose and sufficient to withstand both the static loads of the services and external loads such as wind. “There was a certain amount of design that we did upfront to ensure that the load could be taken on these ‘goal posts’ as per manufacturer’s tested and calculated data,” said Skye.

(Source: Imtech Engineering Services)

Finding the right components…

A mixture of Framo sizes were used; Framo 100 on the side where there were no AHU’s, and Framo 160 for the two main spines of the frame where the units and loads were. With certain things, you can’t tell how much of an effect it will have until you calculate the dynamic wind loads. We allow for dead loads, while the structural engineer applies the dynamic wind loads – and that’s where bracing comes in.

Moreover, because this was assembled onsite, there needed to be an installation guide to ensure that every STA-F-80 should have 8 bolts. Though full structural calculations were made, these would be null and void if the platform was assembled incorrectly, which is why an installation guide is important.

Handrailing was also something to consider. Initially, we had GRP grating made into cuts for hand rails, but that allowed for flexibility on site; and because a good portion of assembly was done on-site. Instead, we swapped to side-mounted handrailing which can be moved along and the handrail could be cut exactly as requested.

The ducting position wasn’t confirmed when we started working on the project and was later provided by ducting suppliers who were working on the project simultaneously. However, we managed to gather all the required information to complete the design.

Slight changes had to be made to the frame, though. Skye explained: “They needed access of least 1m for maintenance of the units and a minimum of 800mm access on the top level for an access route behind one of the units.”

What were the main challenges of the project?

The main challenge faced during this project was coordination.

With multiple people working on the project changing things, it made it quite difficult to finalise a design. Small changes such as how the units would be fixed to the frame affected fairly significant parts of the design, such as the grating.

On the lower floor in particular, where the inner posts were sat to support the top floor, the grating had to be cut or positioned in such a way that it could be fixed around these posts which in some cases affected how many different sheets were required to sit beneath the AHU, given every edge of the grating required support.

To add, there were roughly 50 to 60 sheets of grating and the labour time would have been immense to cut each one; instead, we ordered it pre-cut.

Fine details had to be paid close attention – for example, because there is a ‘top’ and ‘bottom’ of the grating, we had to ensure that it was the right way round, and even change it at times. Small things like this on such a large job can be quite easily missed.

(Source: Imtech Engineering Services)

Supply issues

On top of all this, everything was being ordered at Christmas, and Sikla, our supplier, closed earlier than we did. With the tight deadline from our customer, we weren’t able to physically stock some products in time. Nevertheless, they accepted that we would deliver most of it and then follow up with the parts that were missing when they arrived.

Skye said: “The design was quite nice, but it was with prefabrication and the things you don’t pick up on until you start the fabrication drawing, where we faced challenges. That was the tricky part.”

Transportation

Originally, the frame was intended to be delivered together, but there was the issue of transportation and getting the units in. To overcome this, we changed the design and chopped it down to top, and bottom. This way, the base frame was built and delivered first so that they could at least make a start, and then the top frame was sent afterwards. But having to change the design completely was very time-consuming.

Learning is critical to the success of future projects

Skye shared that one of the main learning outcomes of this project is to involve the workshop earlier on. “All the grating sheets, putting it together and everything, conversations need to be had about this earlier on, because it affects the design. It takes hours and hours when you have to change something, so I think those considerations are much better thought about early on.”

The same can be said about ordering parts In an instance where the customer might change their mind about something, or we don’t get the order on time, etc., a significant amount of money would be spent on wasted products – but this was only an issue due to it being Christmas time. Nevertheless, it’s always good to be upfront about lead times and such.

Although there were quite a few things to consider, having a model, drawings, and everyone involved speaking directly to us, the process was made easier. In the end, the project was extremely successful and our customer, Imtech, was satisfied.

If you are wondering what to expect from our design and off-site fabrication team this article may help to inform you.

Access platform design drawing.