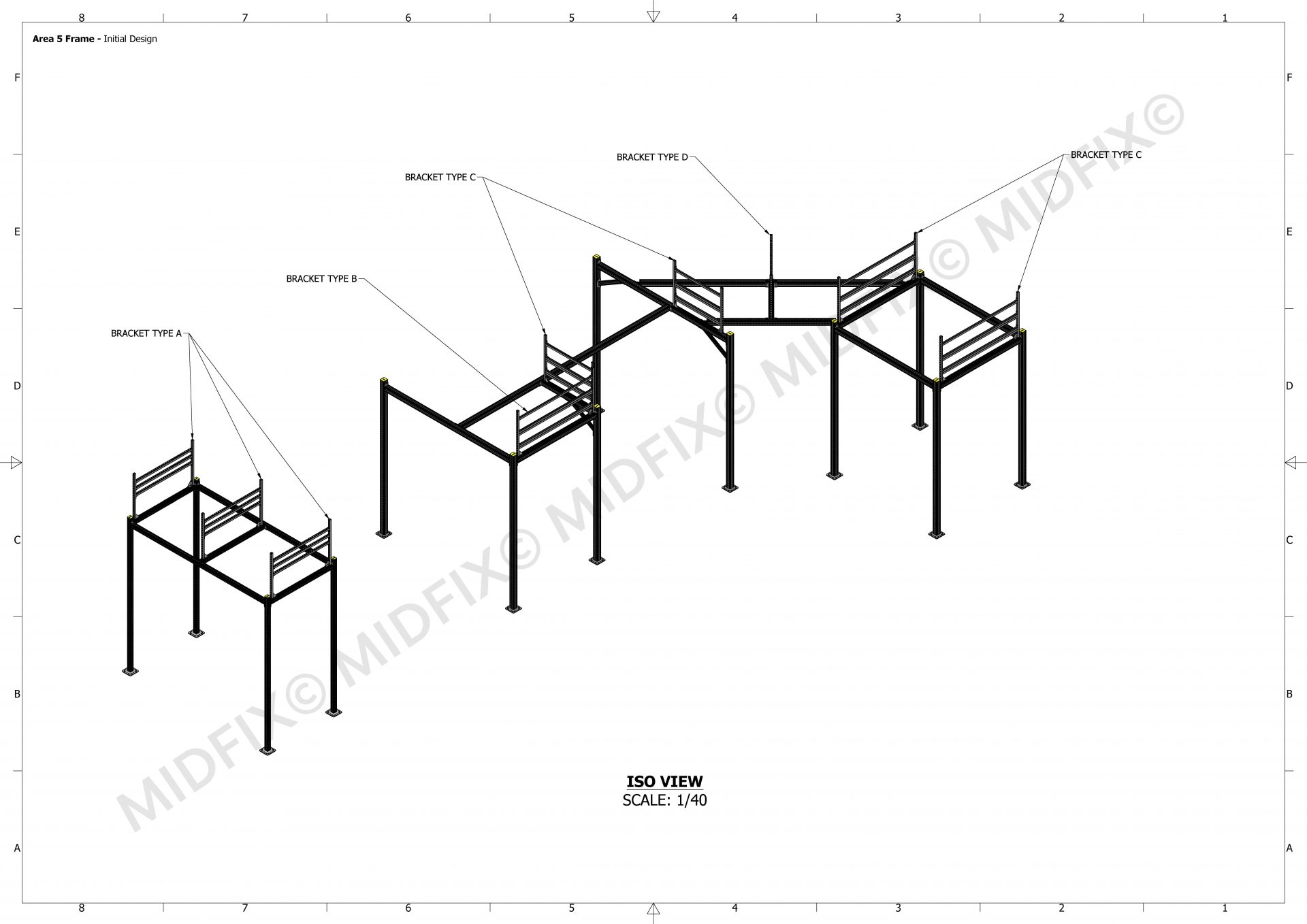

Project Brief: Design and manufacture support frames for heavy-duty cable containment within a tight deadline.

CAD technician Fergus Moran had been briefed to design support frames that could safely support heavy-duty cable containment 3.5 metres off the ground. He takes us through the key moments and challenges that he overcame when creating these designs.

“After speaking with the sales team, project manager, and the customer it was clear this was a large-scale project. Supporting 125 kg/m of cable containment over a walkway, was a challenge. Have you ever considered that M&E supports are akin to a tree? The trunk of the tree must be strong as when the branches and the twigs grow it puts extra strain on the base.

Five metre span

Challenges

With all designs, there are two main challenges that remain the same, the weight of the services and the location.

In this case, the frames had to support 125 kg/m of cable containment, 3 to 4 metres off the ground. It became clear after checking the maximum stresses and deflections that the service loads imposed required the base frame to be made from Framo modular steelwork thanks to its high strength to weight ratio.

The design needed to consider the installation of the cable run as they were being winched through the brackets meaning extra load would be placed on the base frame.

Framo support frame

The location of the frame provided another challenge – as the brackets were over a walkway, it meant spans were sometimes up to 5 metres. To overcome this, diagonal bracing was used in the corners of the longest spans to help minimise stress and deflection. Furthermore, the legs of each frame were anchored into the substrate using correctly specified and tested concrete screws to ensure the overall stability of the frame.

Support frame for cable containment

The service goal post supports were designed to sit on top of the Framo modular steelwork structure. These multi-tiered goal posts were fabricated in our in-house design & innovation centre to specification to ensure a quick assembly to the main structure.

Visiting the site to see the installation by I.C Electrical brought home the sheer size of the support frames.

Overall, this was a relatively stress-free project, thanks to the knowledge gained from previous projects and an understanding of the load capabilities of the different profiles.”

CAD drawing