How we built the Rocket – Freemans Common Core Riser

MIDFIX utilises the latest off-site manufacturing principles to build a core riser for prestigious university development in the East Midlands.

We were recently engaged by a client to build a core riser for prestigious university development in the East Midlands. The riser would supply core services to four floors of the building. For both our client and for us here at MIDFIX, it was obvious from the outset that this was a task of significant proportions.

How we built the Rocket

Aptly named the rocket, due to the fact that when we pulled the core riser from the original building model it bore some resemblance to a space launch site.

Core Riser

Building the core riser

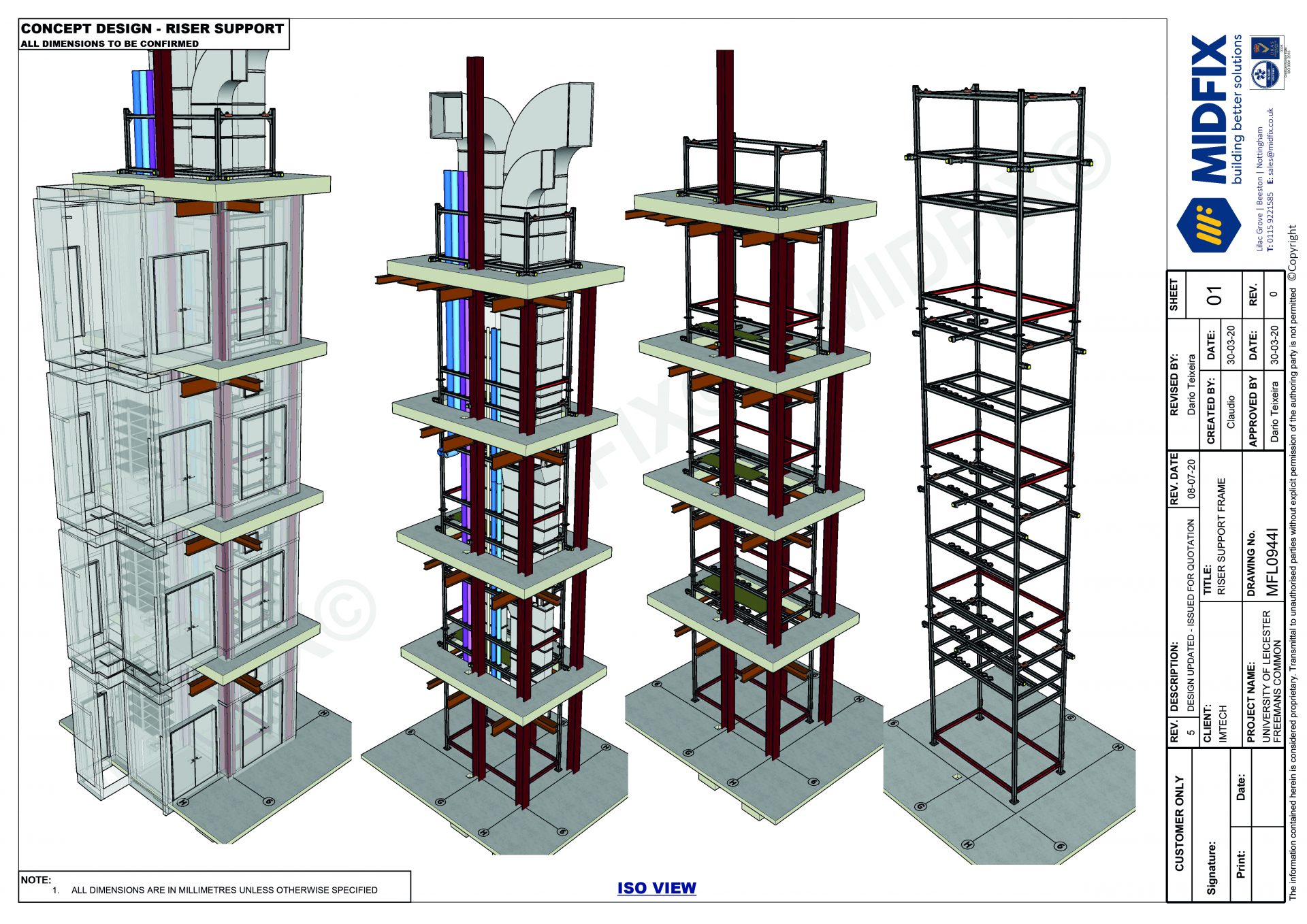

Due to onsite constraints, there was very little margin for error, so it was fundamental that all our teams got it right first time. A project of this scale requires it to be designed and engineered in a 3D technical environment.

Our design team came across some significant challenges. Due to the height of the riser and the material used, we had to come up with a solution that would not overstress the box section. Therefore we had to redesign the load path of the structure by transferring the vertical load of the structure, laterally to the existing floor slabs. This was achieved by introducing four cantilever arms connecting from the structure to each floor slab.

The structural frame was calculated based on Eurocode structural design standards. Therefore, all service loads, stresses and reactional forces were carefully assessed to ensure that the proposed structural frame was fit for purpose.

Our fabrication and assembly team set to work building the structure. Due to the modular nature of the steelwork, we were able to assemble the main structure in just a few hours. Following this, we installed GRP flooring for each floor level. The frame was now ready for the M&E installers to get to work fitting out the frame with all the required services.

Collaborative communication

Keeping an open dialogue is one of the fundamental reasons why projects succeed. We learned early in the project the importance of crystal clear and open communication with the client, their subcontractors, and internally between the design department and the sales team.

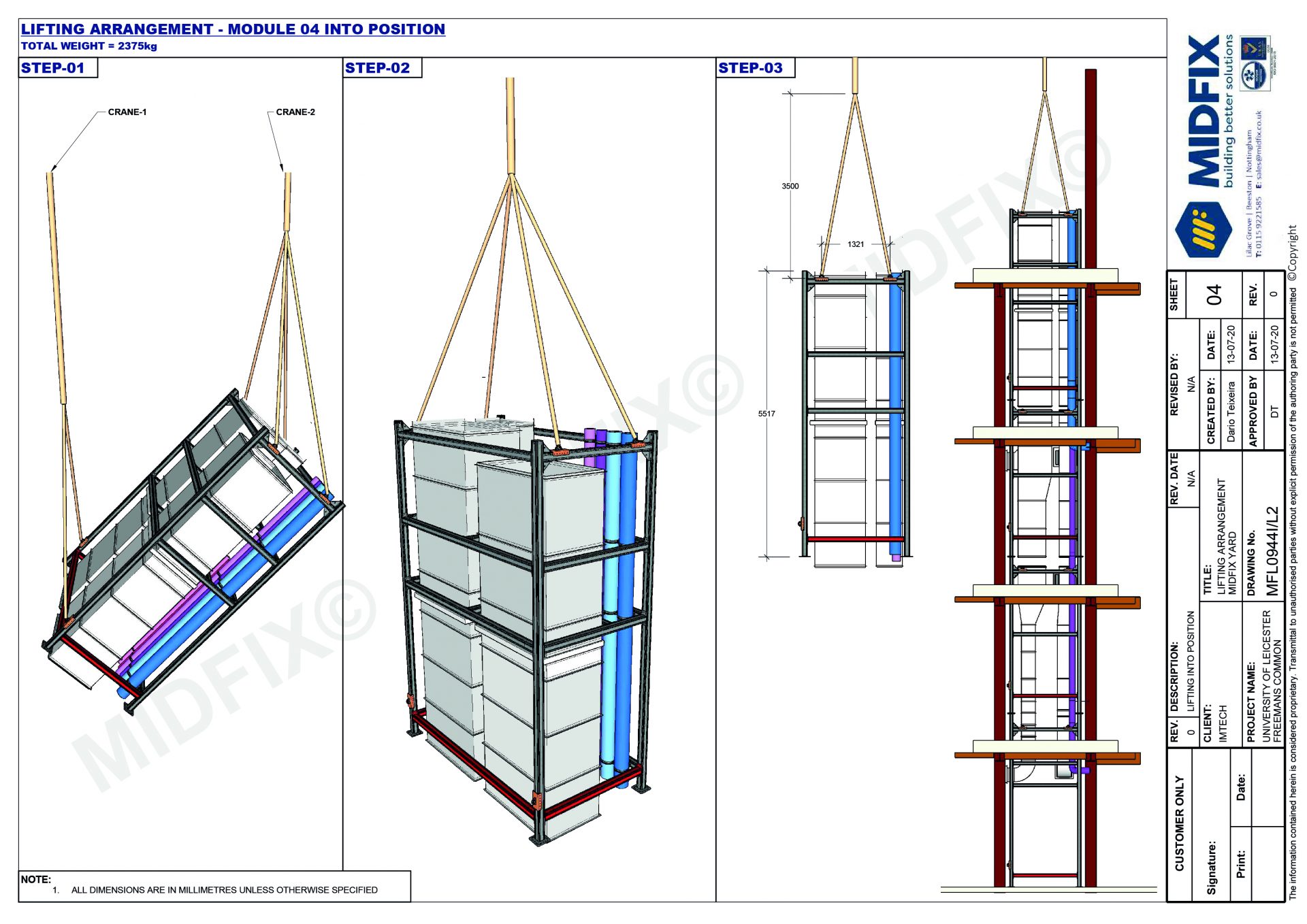

Transporting the rocket

Once the build phase of the project was complete, standing at 26.7 metres tall and over 4 metres wide, the riser had to be broken down into four separate modules in order to be safely transported. Due to the size of the riser modules, it was classed as an abnormal load requiring a movement order and all local authorities had to be given two days’ notice before arrival on-site.

Transporting the riser

Technical drawing showing core riser lift

Lifting the core riser

Core riser module

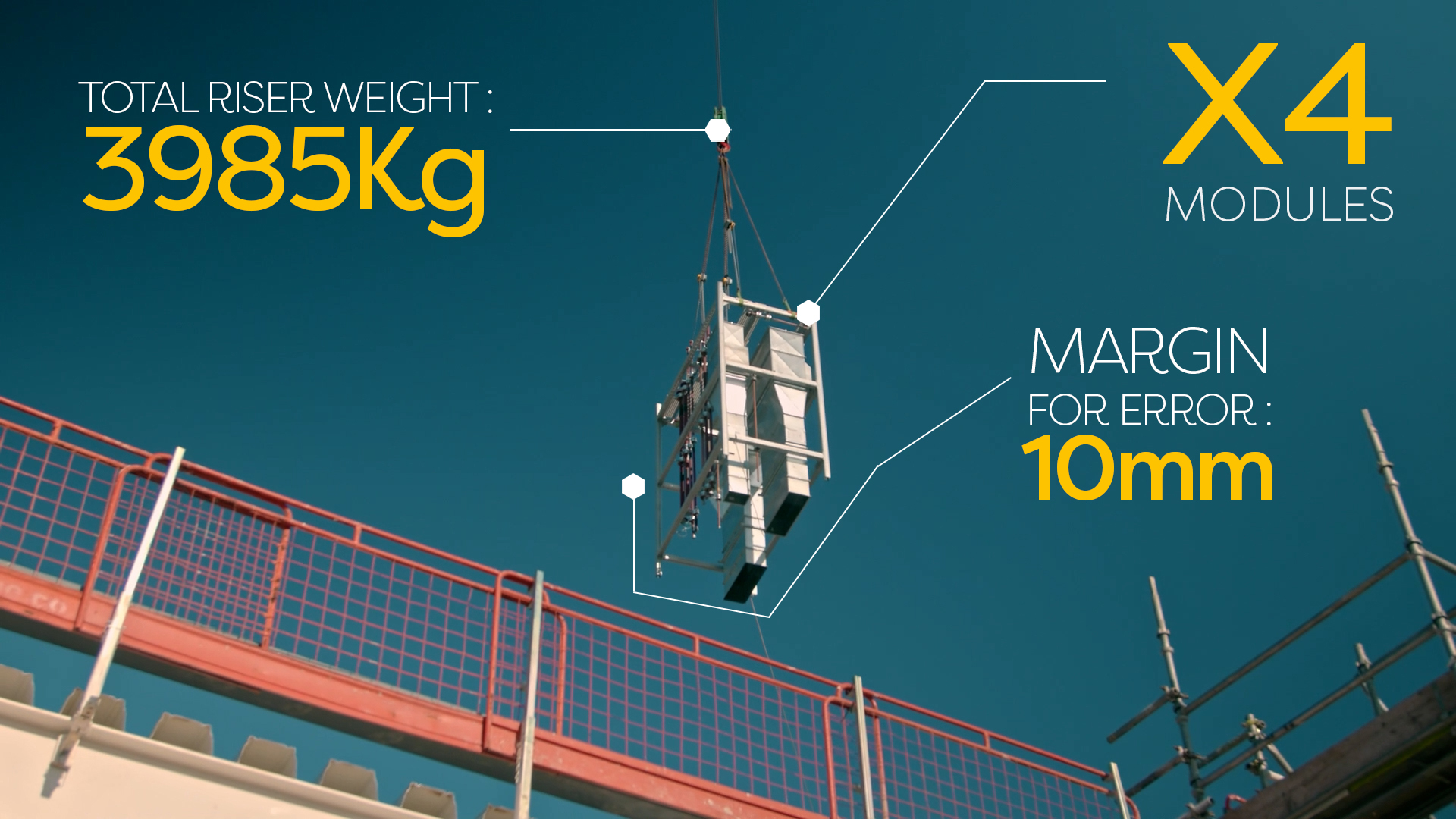

Each module was then crane lifted into the riser shaft, in the correct order with just millimeters of clearance on each side.

Positioning the riser

Outcome

In conclusion, this project saved time, cost, and waste whilst demonstrating the rising sustainable approach within the construction industry. The main structure was built in less than a day and the completed structure was installed on-site within a day. This is a clear example of how the industry is moving towards off-site construction.

After overseeing the project from commission to completion Victoria Wilde project manager of MIDFIX was deservedly satisfied.

When you have the chance to see a project come to life, and see each module lifted in one by one and fitting into place, that’s when you know your team have achieved something special!

Lowering the core riser

Core riser in place

For further information on our technical solutions, request a brochure today.